I dreaded yesterday all week long. Yesterday was stamp-making day.

I currently have nine reliquary commissions, and each of them requires that a stamp is made. I’ve been putting off making the stamps for as long as possible. Three years ago, when I first began making these pieces, I remember spending two solid days, from 8 am to 8 pm working on ONE stamp, that I just couldn’t get right. The lines kept muddying together, so I’d lighten the image and then the lines would rub right off. I was in tears, failure after failure and I was so worried about disappointing the customer and so frustrated that I couldn’t produce a fuctional stamp. Then I started using TNF, I fine tuned my method, and the stamps started to work! It took a lot of trial and error, but in the end I was able to get a pretty good system in place.

Then…the demise of TNF. The product has been discontinued! So I knew I’d have to spend at least a day (and I dreaded it would be weeks or months of trial and error) trying to figure out how to make the stamps minus TNF. Luckily, fate intervened and I met my sister wife, Sue McNenly. Sue is my Accountability Partner in Tonya Davidson’s Artful Success and I think I can safely say, my queen of PPP. She assured me she’s NEVER used TNF, swears by the low relief steel backed plates from Whole Lotta Whimsey, and produces clean, fine lines like a champ.

So, with Sue’s support and the motivation from Artful Success, my “frog of the day” yesterday was to work on those dang stamps. And it was love at first rub.

Somehow, I had it in my head that I needed to expose the stamp for 3 minutes under the light. Nope. 40 seconds. Removing the polymer from the polyester backed plates tended to take at least 3 minutes of vigorous scrubbing…steel back plates? About a minute. The entire stamp-making process went from 10 minutes to less than 3.

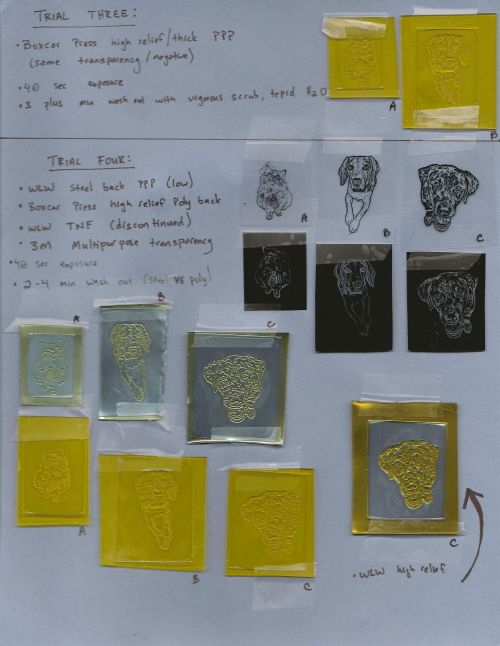

I did a bunch of experiments and you’ll find my results below. Yes, the TNF does create a nice, clear image. However, I found that using the higher relief steel back plates OR the high relief polyester backed backed plates gives you virtually the same result, at least in the stamps I tried.

I did one image with very faint lines and a lot of white space (A), one with medium lines (B) and one with thick, mottled lines (C). Image C had consistantly good results regardless of the backing, depth or use of TNF.

- Image A

- Image B

- Image C

- TNF Results

- Trial 1 and 2

Trial One: Using WLW Steel Backed, Low Relief PPP’s

Images were printed out on3M Multipurpose Transparency film and printed with maximum DPI. Images were exposed for 30 seconds and scrubbed with a soft toothbrush and warm to hot water (the water at my store gets VERY hot, so I had to continue to add cold). Stamps were then cured for 3 minutes. It took very little scrubbing to remove the polymer from the low relief steel back stamps. It took slightly longer with the high relief/thick steel back plates (I was also ran out of hot water so the water had become quite cold)

I felt the images could have been a little deeper, so in Trial Two I increased the exposure time to 40 seconds and turned the temperature of the water to TEPID

In Trial Three, I used Boxcar Press’s high relief/thick PPP’s with polyester backs. I used the same transparency negatives, did a 40 second exposure and a 3 minute cure at the end. It took a lot more work to get the polymer off the poly backed stamps, and I was a lot more aggressive with my scrubbing.

Trial Four was the TNF Trial! I used the low relief steel plates from WLW, one high relief steel back and the thick poly plates from Boxcar. First I had to create the TNF, and then I followed the same exposure/wash out time as in Trial Two and Three.

Trial Five was kind of a bust. I used Imagepac Stampmaker Imageblack sheets to print out the negative. Used an HP printer with the max density of ink. 30 second exposure, less than 2 minute wash out with warm water. I was so unimpressed that I didn’t go further with experimenting with this particular transparency.

At this point, I’m perfectly happy using the steel backed low relief plates from WLW and no TNF! It CAN be done. And now, the results, TA DAAA! Sorry, I couldn’t be bothered to bake the polymer, hope it shows up enough to give you a clear idea. Plus they all shifted around on the scanner. The top row, last impression was using the high relief steel back plate.

I’m happy to conclude that the non-TNF stamps will work perfectly well for my reliquaries!

These scans go from bad to worse. I’ve been at this all day and have a headache. This is what you get. Ok, so the top row is the low relief WLW steel plates, bottom row is the Boxcar Press thick PPP’s and to the far right is WLW thick steel

Any questions? Feel free to contact me!